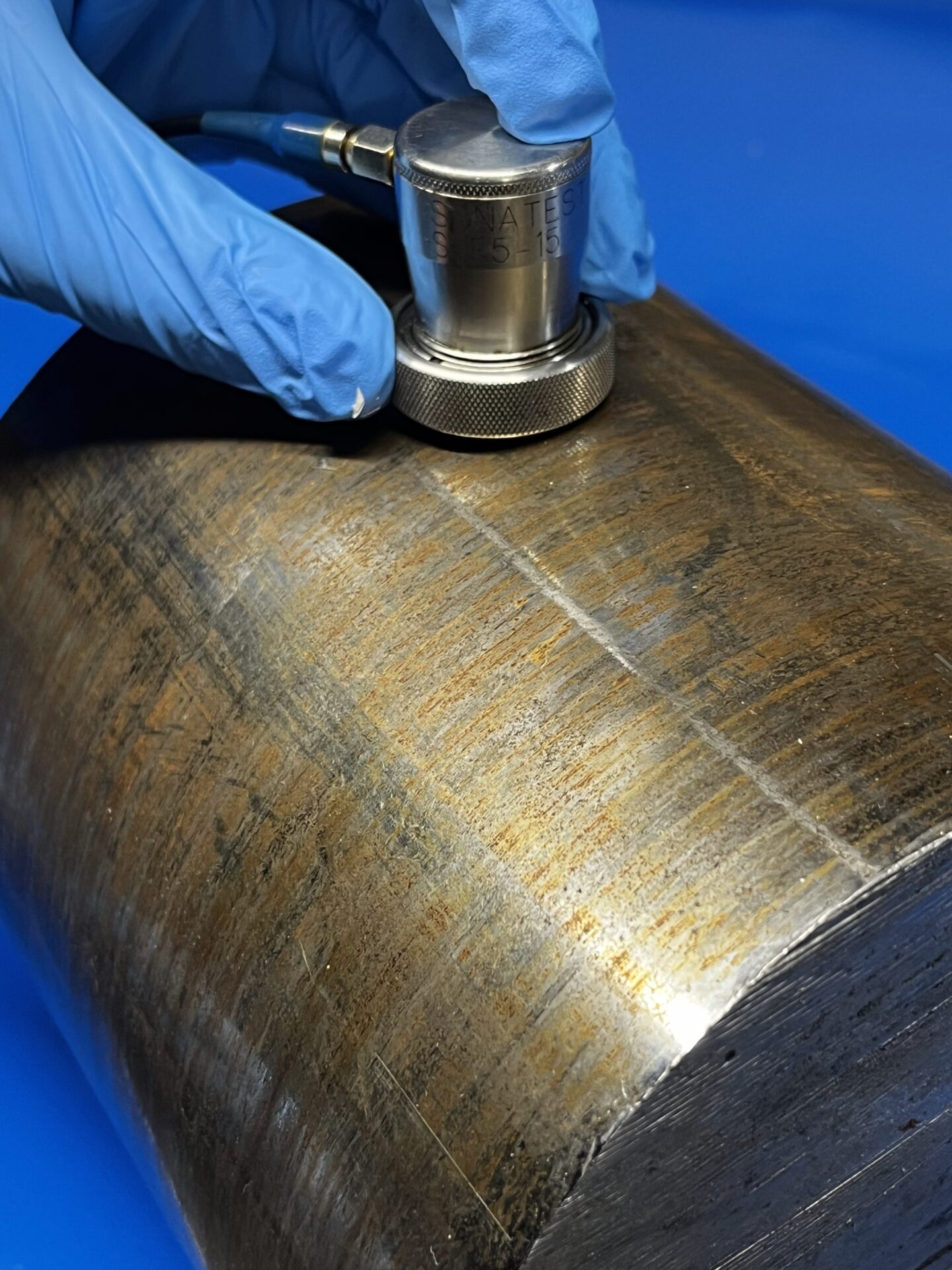

Metal Bar Stock Testing

At Capital NDT, we ensure all testing equipment for metal bar stock is calibrated using ASTM E127-certified blocks. We also use alloy-specific reference blocks in accordance with AMS-STD 2154 and ASTM 2375 to ensure accurate flaw detection.

Our full inventory of calibration and reference blocks across multiple metals—steel, aluminium, titanium, copper alloys, and more—allows us to deliver precise, reliable results. This rigorous approach minimizes the risk of false positives or negatives in flaw assessment.

As a trusted partner for bar stock testing, we combine technical excellence with the capacity to handle large orders quickly and efficiently. Contact us today to learn how our testing services can support your quality assurance goals.

The Benefits of Choosing Capital NDT for Bar Stock Testing:

- Capacity for large orders

- Fast and efficient turnaround times

- Our calibrated reference block inventory includes steel, copper, aluminium, titanium and more

- Certified reference blocks include AMS-STD 2154 / ASTM E2375 / ASTM E127

How can we help you?

Contact us today to find out how Capital NDT can help you with our wide range of non-destructive testing services.

AMS-STD 2154, ASTM E2375 & ASTM E127

AMS stands for Aeronautical Material Specification. AMS-STD 2154 was developed from MIL-STD 2154 a US Department of Defence military standard. It provides a uniform method for the ultrasonic inspection of wrought metals and wrought metal products.

ASTM E2375 is an equivalent standard for the calibration process using a reference block. E127 refers to the standard level of precision in the predrilled faults within the calibration blocks themselves.

The Importance of Calibration

Bar stock must be tested for faults through ultrasonic testing. In order to prove the validity of the data received from the ultrasonic set, we must perform a calibration test. This involves scanning the calibration block in order to find premade faults within a calibration reference block. These faults are drilled to different depths, in accordance to the ASTM E127 standard and upon scanning – should the set find the fault – we can prove that the settings on the ultrasonic set can be used.

Not all bar stock is made from the same material and neither are the calibration blocks! Due to the structure of different metals, ultrasonic waves react differently within different metals. It is therefore key to hold multiple sets of calibration blocks in different metals, the most common being steel, aluminium and titanium. Once the ultrasonic set finds the premade fault in the specific calibration block, testing can be undertaken as normal.

What is the Process?

Bar stock must be tested for faults through ultrasonic testing. In order to prove the validity of the data received from the ultrasonic set, we must perform a calibration test. This involves scanning the calibration block in order to find premade faults within a calibration reference block. These faults are drilled to different depths, in accordance to the ASTM E127 standard and upon scanning – should the set find the fault – we can prove that the settings on the ultrasonic set can be used.

Not all bar stock is made from the same material and neither are the calibration blocks! Due to the structure of different metals, ultrasonic waves react differently within different metals. It is therefore key to hold multiple sets of calibration blocks in different metals, the most common being steel, aluminium and titanium. Once the ultrasonic set finds the premade fault in the specific calibration block, testing can be undertaken as normal.

Why Choose Capital NDT?

With a full range of calibration blocks in multiple metals, you only need to make one call. We can handle any request large or small, turned around efficiently and to the highest standards.

Our team of NDT technicians are all qualified with industry recognised PCN (Personnel Certification in Non-Destructive Testing) in accordance with BS EN ISO 9712, as well as EN 4179, NAS-410, SNT-TC-1A. Our testing facility is also accredited by a number of well-known bodies, including ADIPS and UKAS.

For More Information On Our NDT Inspection Services

or by filling out our contact form: